Understanding Ball Chain Manufacturing and Its Role in Modern Industries

Ball chain manufacturing creates strong and adaptable chains used in many industries. These chains consist of small, interconnected metal balls that provide both strength and flexibility. You can find them in everyday objects like keychains, ceiling fan pulls, or even industrial equipment.

Their importance lies in their ability to combine function with style. Whether for securing items or enhancing designs, these chains deliver solutions that are practical and visually appealing. Their versatility makes them a valuable tool in modern manufacturing and design processes.

Önemli Çıkarımlar

- Ball chains are tough and bendable, perfect for many uses like jewelry or tools.

- Picking materials like stainless steel or brass makes them last longer and look better.

- You can customize ball chains by choosing materials, colors, and sizes to match your needs.

- Modern methods make strong and good-looking ball chains with high quality.

- Many ball chains are recyclable, helping the environment and supporting green practices.

What Is Ball Chain Manufacturing?

Tanım ve Amaç

Ball chain manufacturing refers to the process of creating chains made up of small, interconnected metal balls. These chains are designed to provide strength, flexibility, and aesthetic appeal. You can find them in a variety of products, from fashion accessories to industrial tools. The purpose of ball chain manufacturing is to produce durable and versatile chains that meet the needs of different industries. Whether you need a chain for decorative purposes or functional use, this manufacturing process ensures high-quality results.

Historical Background and Evolution

The origins of ball chain manufacturing date back to the early 20th century. Initially, these chains were used in simple applications like securing items or as pull chains for lamps. Over time, advancements in technology allowed manufacturers to improve the design and production methods. Today, ball chains are made using modern techniques that enhance their durability and appearance. The evolution of this industry reflects the growing demand for products that combine functionality with style.

Overview of the Manufacturing Process

The manufacturing process for ball chains involves several steps. First, manufacturers select the appropriate material, such as stainless steel, brass, or aluminum. These materials are then shaped into small, uniform balls. Next, the balls are connected using precision machinery to form a continuous chain. Quality control measures ensure that each chain meets industry standards for strength and flexibility.

To understand the scope of ball chain manufacturing, consider the following market research data:

| Aspect | Details |

|---|---|

| Market Segmentation | Split by Type (Plated Metal, Non-gold Plated) and by Application (Automobile, Chemical, etc.) |

| Competitive Landscape | Insights into market share, competitive advantages, and differentiation among players. |

| Consumer Analysis | Data on consumer behavior, preferences, and attitudes towards Aluminum Chain. |

| Regional Analysis | Covers North America, Europe, Asia-Pacific, South America, and Middle East & Africa. |

| Market Dynamics | Includes drivers, restraints, trends, and Porter’s Five Forces analysis. |

| Key Players | Associated Fastening Products, BudgitHoist, Tsubaki Inc., and others. |

| Forecast Period | 2019-2030 for consumption value by Type and Application. |

This data highlights the diverse applications and global reach of ball chain manufacturing. It also shows how the industry continues to adapt to changing market demands.

Materials and Techniques in Ball Chain Manufacturing

Common Materials Used

The materials used in ball chain manufacturing play a crucial role in determining the chain’s strength, durability, and appearance. You will often find stainless steel as a popular choice due to its resistance to rust and corrosion. Brass is another common material, valued for its attractive golden hue and malleability. Aluminum, known for being lightweight yet sturdy, is also widely used.

For specialized applications, manufacturers may use nickel-plated or chrome-plated metals. These coatings enhance the chain’s durability and give it a polished finish. By selecting the right material, manufacturers ensure that the chains meet the specific needs of various industries.

Advanced Manufacturing Techniques

Modern ball chain manufacturing relies on advanced techniques to produce high-quality chains efficiently. Precision machinery is used to shape the metal into uniform balls. These balls are then connected seamlessly to form a continuous chain.

Some manufacturers use automated processes to increase production speed and maintain consistency. Laser cutting and welding techniques are also employed to ensure precise connections between the balls. These innovations not only improve the chain’s strength but also enhance its aesthetic appeal.

Quality Control and Standards

Quality control is a vital part of ball chain manufacturing. Manufacturers perform rigorous testing to ensure that each chain meets industry standards. You might notice that chains undergo stress tests to check their strength and flexibility.

Visual inspections are also conducted to identify any defects or irregularities. Some companies follow international standards, such as ISO certifications, to guarantee product reliability. By maintaining strict quality control, manufacturers deliver chains that are both functional and durable.

Key Features and Benefits of Ball Chains

Durability and Longevity

Ball chains are built to last. Their design and materials ensure they can withstand wear and tear over time. When you choose a ball chain made from stainless steel or brass, you get a product that resists rust and corrosion. This makes them ideal for both indoor and outdoor use.

Did you know? Ball chains are often used in environments where durability is critical, such as industrial machinery or safety equipment. Their ability to endure harsh conditions makes them a reliable choice for demanding applications.

You can count on ball chains to maintain their strength and appearance even after years of use. This durability reduces the need for frequent replacements, saving you time and money in the long run.

Flexibility and Versatility

One of the standout features of ball chains is their flexibility. The interconnected ball design allows the chain to bend and move freely without breaking. This makes them perfect for applications where movement is essential, such as pull chains for ceiling fans or adjustable straps for bags.

Ball chains also adapt to a wide range of uses. Whether you need them for decorative purposes, functional tasks, or industrial applications, they deliver consistent performance. Their versatility ensures they meet the needs of various industries, from fashion to manufacturing.

Customization for Specific Applications

Ball chains offer endless customization options. You can select from different materials, finishes, and sizes to match your specific requirements. For example, you might choose a chrome-plated chain for a polished look or a lightweight aluminum chain for ease of use.

Manufacturers often provide options for custom lengths and designs. This allows you to create a chain that fits your unique needs perfectly. Whether you’re designing a stylish necklace or a secure keychain, ball chains give you the flexibility to bring your vision to life.

Ball Chain Manufacturing plays a crucial role in delivering these customizable solutions. By using advanced techniques and high-quality materials, manufacturers ensure you get a product that meets your expectations.

Applications of Ball Chains in Modern Industries

Fashion and Accessories

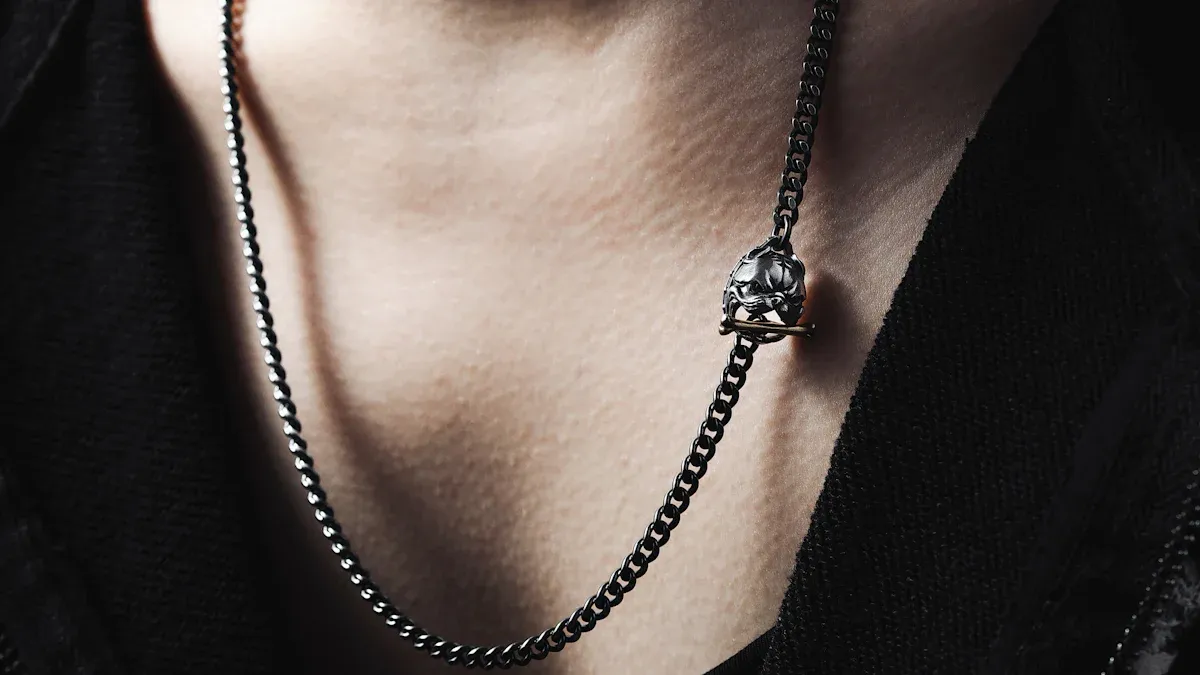

Ball chains have become a staple in the fashion world. You often see them in necklaces, bracelets, and anklets, where their sleek design adds a modern touch. Their lightweight nature makes them comfortable to wear, while their durability ensures they last for years. Designers frequently use ball chains to create adjustable straps for bags or belts, giving you the flexibility to customize your accessories.

İpucu: If you’re looking for a unique way to personalize your jewelry, ball chains can be paired with pendants or charms to create one-of-a-kind pieces.

Their versatility extends beyond jewelry. Ball chains are also used in clothing, such as decorative trims on jackets or dresses. This adds a subtle yet stylish detail that enhances the overall design.

Industrial and Commercial Uses

In industrial and commercial settings, ball chains serve practical purposes. You’ll find them in machinery, where they act as pull chains for operating equipment. Their strength and flexibility make them ideal for environments that require reliable performance.

Ball chains are also used in signage systems. They help suspend signs securely while allowing easy adjustments to height or position. In commercial spaces, ball chains often appear in lighting fixtures, such as pull chains for lamps or ceiling fans.

Did you know? Ball chains are commonly used in keychains for securing keys in workplaces or factories. Their robust design ensures they can withstand daily use without breaking.

Home Décor and Design

Ball chains bring both functionality and style to home décor. You might use them as pull chains for ceiling fans or blinds, where their smooth operation adds convenience to your daily life. Their polished finish complements modern interiors, making them a popular choice for decorative purposes.

Home designers often incorporate ball chains into furniture or lighting designs. For example, they may use them as accents on lampshades or as connectors for hanging planters. These chains add a contemporary flair to your living space while maintaining practicality.

Not: Ball chains can also be used for DIY projects. Whether you’re creating custom curtain tiebacks or decorative wall hangings, their adaptability makes them a favorite among craft enthusiasts.

Ball Chain Manufacturing plays a vital role in producing these versatile chains, ensuring they meet the demands of both functional and aesthetic applications.

Safety and Security Products

Ball chains play a vital role in safety and security products. Their strength, flexibility, and reliability make them an essential component in various applications designed to protect you and your belongings.

One common use of ball chains is in identification tags. You often see them paired with dog tags or medical alert tags. These chains are lightweight and comfortable to wear, yet strong enough to hold important identification securely. Their durability ensures they remain intact even in challenging conditions.

İpucu: If you need a chain for an ID tag, choose stainless steel. It resists rust and lasts longer, especially in outdoor environments.

Ball chains are also widely used in safety equipment. For example, they serve as pull chains for emergency showers or eyewash stations in industrial settings. Their smooth operation allows you to activate these devices quickly during emergencies. Additionally, their corrosion-resistant materials ensure they function reliably in harsh environments.

In the security sector, ball chains are often found in key retention systems. They help secure keys to belts or workstations, reducing the risk of loss. You might also notice them in tamper-evident seals, where they provide a secure yet flexible connection.

- Key Features of Ball Chains in Safety Products:

- High tensile strength for secure connections.

- Resistance to wear and tear in demanding environments.

- Customizable lengths to suit specific needs.

Ball chain manufacturing ensures these products meet strict safety standards. By choosing high-quality ball chains, you can enhance the reliability and effectiveness of your safety and security solutions.

The Significance of Ball Chain Manufacturing

Enhancing Functionality Across Industries

Ball chain manufacturing plays a vital role in improving functionality across various industries. These chains provide smooth and reliable operation in products like window blinds and ceiling fans. Their design ensures hassle-free use, making them a practical choice for both residential and commercial applications. You can also rely on their durability, as they resist rust and wear, even in challenging environments.

In industrial settings, ball chains enhance the performance of machinery by offering secure and flexible connections. Their ability to withstand heavy use makes them indispensable in manufacturing processes. Additionally, their customization options allow industries to adapt these chains for specific needs, ensuring they meet unique operational requirements.

Contribution to Design and Aesthetics

Ball chains are not just functional; they also contribute significantly to design and aesthetics. Their sleek and polished appearance adds a modern touch to fashion accessories, home décor, and even industrial products. Designers often use these chains to create visually appealing items that stand out.

For example, in window blinds, ball chains combine superior craftsmanship with smooth operation, enhancing both the look and functionality of the product. Their versatility allows you to choose from various materials, finishes, and sizes, ensuring they match your design preferences. Whether you’re creating jewelry or decorating a space, ball chains offer endless possibilities for customization.

Supporting Innovation and Sustainability

Ball chain manufacturing supports innovation by utilizing advanced techniques and materials. Manufacturers use precision machinery and automated processes to produce high-quality chains efficiently. These innovations not only improve the product but also reduce waste during production.

Sustainability is another key aspect. Many ball chains are made from recyclable materials like stainless steel and aluminum. This reduces environmental impact and promotes eco-friendly practices. By choosing products made through sustainable methods, you contribute to a greener future while enjoying the benefits of durable and versatile chains.

Ball chain manufacturing plays a vital role in modern industries. It provides you with durable, flexible, and customizable solutions that enhance functionality across various applications. These chains also contribute to innovative designs, blending practicality with aesthetic appeal.

Not: By choosing ball chains, you support sustainable practices. Many are made from recyclable materials, promoting eco-friendly industrial growth.

From improving everyday products to driving advancements in manufacturing, ball chains continue to shape industries. Their versatility and reliability make them an essential component in today’s world.

SSS

What are ball chains made of?

Ball chains are typically made from materials like stainless steel, brass, or aluminum. These materials ensure durability and resistance to wear. For specific needs, manufacturers may use nickel or chrome plating to enhance strength and provide a polished finish.

How do you maintain ball chains?

To maintain ball chains, clean them with a soft cloth and mild soap. Avoid harsh chemicals that may damage the finish. For stainless steel chains, occasional polishing keeps them shiny and rust-free. Proper care ensures they last longer.

İpucu: Store ball chains in a dry place to prevent corrosion.

Can ball chains be customized?

Yes, ball chains offer extensive customization options. You can choose different materials, finishes, and lengths to suit your needs. Manufacturers also provide options for unique designs, making them ideal for personalized jewelry, industrial tools, or decorative items.

Are ball chains safe for industrial use?

Ball chains are safe and reliable for industrial applications. Their strength and flexibility make them suitable for heavy-duty tasks like operating machinery or securing equipment. High-quality materials ensure they perform well even in demanding environments.

Why are ball chains popular in fashion?

Ball chains are lightweight, durable, and stylish. Their sleek design complements modern jewelry and accessories. You can pair them with pendants or charms to create unique pieces. Designers also use them in clothing and bags for added functionality and aesthetic appeal.

Did you know? Ball chains are often used in adjustable straps for their flexibility.

Thanks for shening. I read many of your blog posts, cool, your blog is very good. https://accounts.binance.com/hu/register-person?ref=IQY5TET4