Choosing the Right DIN 766 Chain

Choosing the right DIN 766 Chain is very important. It helps keep your work safe and running smoothly. These chains are strong and dependable for tough jobs. Knowing the types and materials helps you pick the best chain. This improves how it works and lowers risks. Whether for boats or factories, the right chain lasts longer. Picking good quality and the right fit protects tools and makes work safer.

Principales conclusiones

- Picking the right DIN 766 chain makes work safer and easier. Think about what your project needs before choosing a chain.

- Learn about the different DIN 766 chain grades. Stronger grades carry heavier weights and handle tough jobs. Weaker grades work better for lighter tasks.

- Choose the right chain material. Use stainless steel in wet places to stop rust. Use carbon steel in dry areas where rust isn’t a problem.

- Always check the chain’s weight limits and safety rules. Make sure the chain’s Working Load Limit (WLL) is higher than the weight you will lift or secure.

- Read the manufacturer’s details to match the chain with your tools. A good fit avoids damage and helps the chain work well.

Understanding DIN 766 Chain Standards

What is DIN 766?

DIN 766 is a set of rules for chains. These chains are used in factories and on boats. It explains the size, strength, and shape of chains. This helps make sure they work well and fit right. If a chain says DIN 766, it follows strict rules for quality. Many industries trust this standard. It makes finding matching tools and parts easier.

Key features of DIN 766 chains

DIN 766 chains are strong and last a long time. Their links are the same size, so they work smoothly. They can carry heavy weights but still bend easily. These chains don’t wear out quickly. They are great for tough jobs.

Here are some main features:

- Standardized dimensions: Fits with many tools and machines.

- High strength: Lifts heavy things without bending.

- Corrosion resistance: Made from materials like stainless steel for wet places.

These features make DIN 766 chains a smart choice for hard tasks.

Applications of DIN 766 chains

DIN 766 chains are used in many places. On boats, they hold anchors and tie up ships. In factories, they move items on conveyor belts and lift heavy things. They work well for both still and moving loads.

If you need a chain for a job, think about DIN 766 chains. Their design helps them work well in both water and factory settings.

Comparing DIN 766 Chain Grades

Overview of chain grades

When picking a Cadena DIN 766, knowing its grades is key. Chain grades show how strong and durable the chain is. Each grade tells you how much weight it can hold. Higher grades are stronger and good for tough jobs. Lower grades work well for lighter tasks.

Here’s a simple guide to common chain grades:

- Grade 30: Called proof coil, it’s for everyday light tasks. It’s great for small loads and non-critical uses.

- Grade 40: Known as high-test chain, it’s stronger. It’s often used in boats and factories.

- Grade 70 and above: These are for heavy-duty jobs like towing or lifting very heavy items.

Knowing these grades helps you pick the right chain for your job.

Grade 30 vs. Grade 40: Strength and uses

Grade 30 y Grade 40 are popular choices for DIN 766 Chains. Both are strong but fit different needs based on their strength.

| Feature | Grade 30 | Grade 40 |

|---|---|---|

| Tensile Strength | Lower, handles light loads | Higher, supports heavier loads |

| Aplicaciones | Everyday, light tasks | Boats, factories, medium tasks |

| Coste | Cheaper | Costs a bit more |

Grade 30 chains are good for tying down cargo or light anchoring. They are not made for high-stress jobs. Grade 40 chains are better for harder tasks. Use them for lifting, towing, or boat work where strength matters.

Consejo: Always check how much weight your job needs before choosing a chain. Using a weak chain can cause accidents or damage.

Picking the right grade for your job

Choosing the right Cadena DIN 766 grade depends on your task. First, think about the weight and type of load. For light jobs, Grade 30 is a budget-friendly choice. For boats or factory work, Grade 40 is stronger and lasts longer.

Think about where you’ll use the chain. For example, chains for boats need to resist rust, which higher grades often do. Also, consider long-term use. Spending more on a stronger chain can save money by lasting longer.

Note: Always check the maker’s guide to ensure the chain is safe and fits your needs.

Materials Used in DIN 766 Chains

Carbon steel vs. stainless steel

When picking a material for a Cadena DIN 766, you’ll see two main choices: carbon steel and stainless steel. Each works well for different jobs.

Carbon steel is strong and less expensive. It handles heavy loads easily and is best for dry places. But it can rust if it stays wet for too long. This makes it less useful for outdoor or water-based tasks.

Stainless steel, however, doesn’t rust and fights corrosion well. It’s great for wet areas like boats or near the ocean. Though it costs more, it lasts longer and needs less care.

Consejo: Use carbon steel for heavy lifting in dry areas. For wet or humid places, stainless steel is the better pick.

Corrosion resistance and durability

Corrosion resistance affects how long a chain will last. Water, chemicals, or bad weather can weaken chains without protection. Stainless steel chains resist rust, making them perfect for boats or factories.

Carbon steel chains are strong but need coatings like galvanization to stop rust. Without this, they wear out faster in tough conditions.

Durability also depends on how you use the chain. Overloading or poor care can make it wear out quickly. Always follow the chain’s care guide to keep it working well.

Material suitability for marine and industrial environments

Where you use your Cadena DIN 766 decides the best material. For boats, stainless steel is the best choice. It resists saltwater and stays strong. It also needs less care, which is helpful for marine use.

In factories, the choice depends on the setting. Carbon steel works well in dry places without rust risks. In moist or chemical-heavy areas, stainless steel lasts longer and protects better.

Note: Match the chain material to its environment. This keeps it safe, reduces upkeep, and makes it last longer.

Key Factors for Selecting a DIN 766 Chain

Load limits and safety considerations

Knowing load limits is important when picking a Cadena DIN 766. You must check how much weight the chain can hold safely. Chains have two main limits: Safe Working Load (SWL) and Working Load Limit (WLL). SWL is the highest weight for normal use. WLL is slightly higher for short-term stress during work.

For loads over 10,000 lbs., use at least four tie-downs. Each tie-down should have a WLL of 5,000 lbs. This keeps the load secure and avoids accidents. Chain grades also matter for safety. Higher grades, like Grade 70, are made for heavy lifting and tough jobs. Always pick the right chain grade to prevent problems.

Consejo: Read the chain’s details and follow safety rules to stay safe.

Environmental conditions and chain performance

Where you use the chain affects how well it works. Chains in water, chemicals, or extreme heat need materials that resist rust and damage. Stainless steel chains are great for wet or humid places, like on boats. They don’t rust and stay strong for a long time.

In dry areas, carbon steel chains are cheaper and work well. But they need coatings to stop rust. If your chain will face bad weather or chemicals, choose one that lasts and resists corrosion.

Note: Pick a chain material that fits the environment for better performance.

Compatibility with equipment and systems

A Cadena DIN 766 should fit your tools perfectly. Its standard size works with many machines and tools. Before buying, check the chain’s size to match your system. Using the wrong chain can cause damage or slow down work.

For special tasks, check the maker’s guide. This ensures the chain fits and works well. Whether lifting heavy loads or securing cargo, the right chain makes the job easier.

Reminder: Always check the chain’s fit to avoid costly errors.

Practical Tips for Choosing the Right DIN 766 Chain

Evaluating your application requirements

First, figure out what your project needs. Think about the load type and where the chain will be used. For heavy lifting, pick a chain with strong tensile strength. For boats or wet areas, choose one that resists rust.

Also, consider how often you’ll use the chain. Chains used daily in factories need to be tougher than those used less often. Safety is important too. If your work is risky, pick a chain grade that can handle more weight than needed. This ensures it won’t fail.

Consejo: List your project needs before buying a chain. This helps you find the right chain without wasting money.

Consulting manufacturer specifications

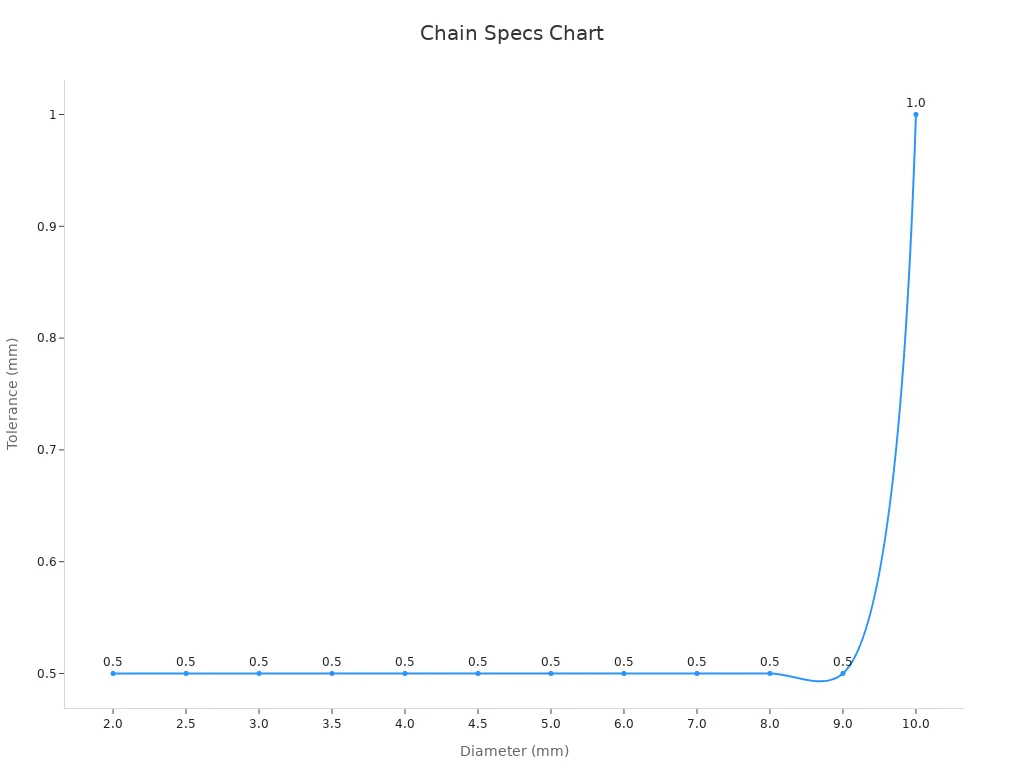

Manufacturer details tell you how a chain performs. These include size, strength, and material. DIN 766 chains have standard sizes, so they fit many tools. Below is a table showing chain sizes and tolerances:

| Diameter (mm) | Tolerancia |

|---|---|

| 2.0 | ±0.5 |

| 2.5 | ±0.5 |

| 3.0 | ±0.5 |

| 3.5 | ±0.5 |

| 4.0 | ±0.5 |

| 4.5 | ±0.5 |

| 5.0 | ±0.5 |

| 6.0 | ±0.5 |

| 7.0 | ±0.5 |

| 8.0 | ±0.5 |

| 9.0 | ±0.5 |

| 10.0 | ±1.0 |

These chains are made to resist rust and stay strong. Below is a chart showing tolerances for different chain sizes:

Note: Match the chain’s details with your project needs to ensure it works well.

Balancing cost, performance, and longevity

It’s important to balance cost, performance, and how long the chain lasts. Stainless steel chains cost more but are better for tough conditions. Carbon steel chains are cheaper but need care to avoid rust.

Think about long-term savings. Spending more on a strong chain can save money by lasting longer. Check how often you’ll use it and the conditions it will face. Chains with higher grades and rust resistance work better and are safer for hard jobs.

Reminder: A good-quality chain keeps you safe and saves money over time.

Knowing about DIN 766 chain grades and materials is very important. Picking the right chain keeps your work safe and efficient. It also makes the chain last longer and avoids problems.

Consejo profesional: If unsure, ask manufacturers or experts for advice. They can help you choose the best chain for your job.

Think about what you need and check your choices carefully. This way, you can get a chain that works well and lasts a long time.

PREGUNTAS FRECUENTES

What does the “DIN” in DIN 766 mean?

“DIN” stands for Deutsches Institut für Normung. This is the German Institute for Standardization. It creates exact rules for chain sizes. These rules ensure chains work well and fit in many industries.

Consejo: Check for the DIN mark to know the chain meets trusted rules.

How can I measure a DIN 766 chain?

To measure a DIN 766 chain:

- Measure the link length both inside and outside.

- Check the link diameter carefully.

- Measure the pitch, which is the space between links.

Note: Use a caliper to get exact measurements.

Can I use a carbon steel chain in wet areas?

You can, but it’s not the best choice. Carbon steel rusts fast in wet or salty places. Stainless steel chains are better because they don’t rust easily.

Reminder: Always pick a chain material that matches the environment.

How can I tell if a chain is strong enough?

Look at the chain’s grade y Working Load Limit (WLL). Higher grades, like Grade 40 or 70, can carry heavier loads. Always pick a chain with a WLL higher than your load.

Consejo profesional: Choosing a chain with extra capacity adds safety.

Do DIN 766 chains fit all tools?

DIN 766 chains have standard sizes, so they fit most tools. But always check the chain size and pitch with your equipment’s guide.

Consejo: Read your tool manual to make sure the chain fits.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me? https://accounts.binance.com/sl/register?ref=I3OM7SCZ

Your article helped me a lot, is there any more related content? Thanks! https://www.binance.com/register?ref=IXBIAFVY

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.