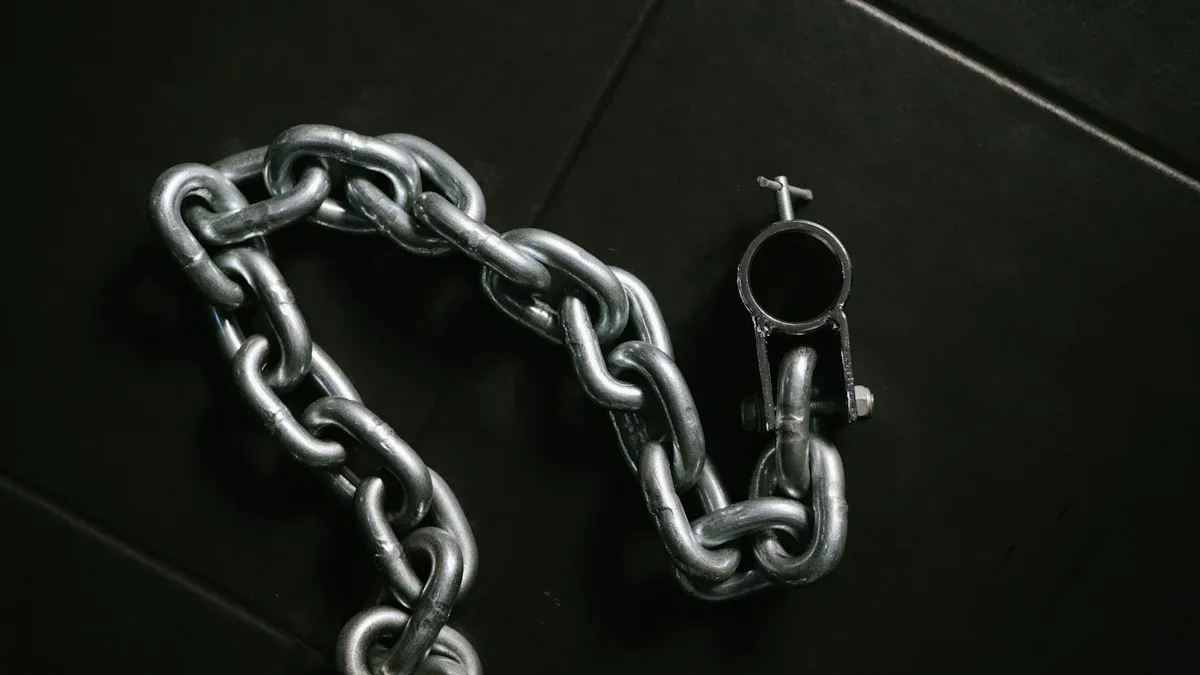

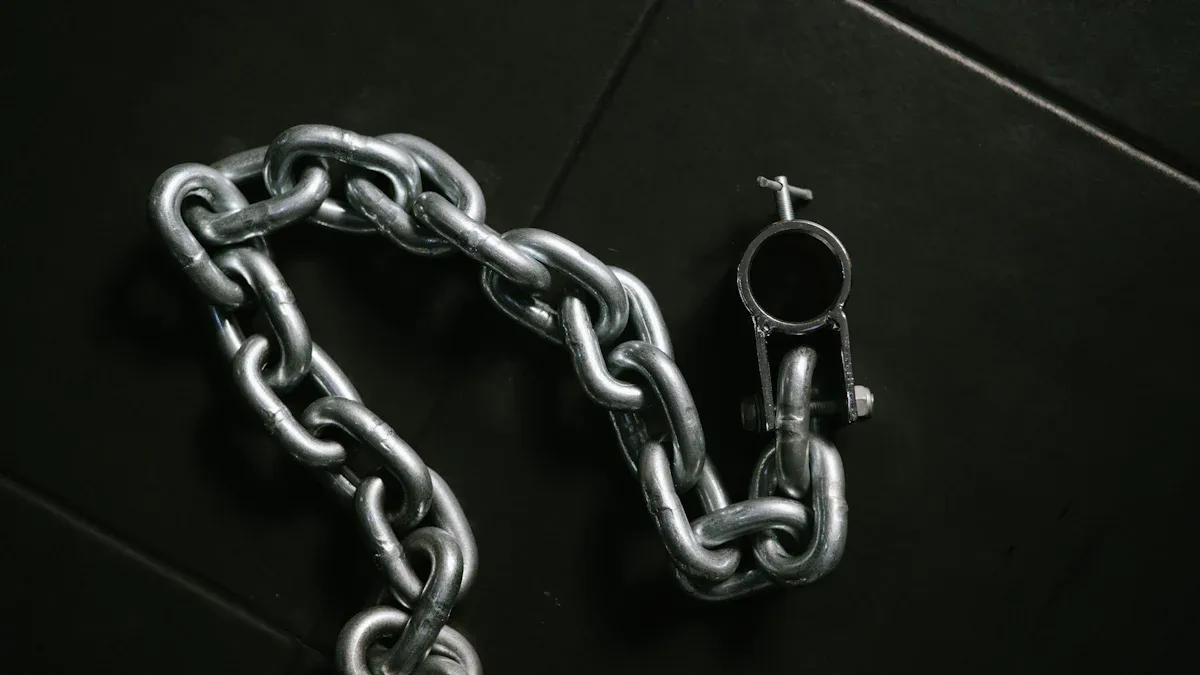

Understanding DIN 763 Chain Standards

DIN 763 Chain refers to a standardized type of long-link chain widely used in industries for its reliability and performance. These chains follow strict guidelines to ensure consistency and safety in various applications. Their design focuses on durability, making them suitable for heavy-duty tasks.

Adhering to DIN 763 standards provides several benefits. It ensures compatibility with equipment, improves operational safety, and guarantees high-quality materials. Standardized chains reduce the risk of failure, offering peace of mind to users in demanding environments.

Principaux enseignements

- DIN 763 chains are strong and dependable, perfect for tough jobs.

- Following DIN 763 rules ensures they fit equipment and stay safe.

- Check DIN 763 chains often for wear, rust, and cleanliness.

- Always check the weight limit to avoid overloading the chain.

- Pick the right chain for the job; don’t use for lifting overhead.

Overview of DIN 763 Chains

Purpose and Key Features

DIN 763 chains are designed to meet the demands of industrial applications. These chains are known for their long-link design, which provides flexibility and strength. They are commonly used in conveying and lifting tasks, ensuring reliable performance under heavy loads. The DIN 763 standard guarantees that these chains meet strict quality and safety requirements, making them a trusted choice in industries worldwide.

Key features of DIN 763 chains include:

- Uniform link dimensions for consistent performance.

- High tensile strength to handle significant loads.

- Resistance to wear and tear, even in challenging environments.

A numerical evaluation of these chains highlights their versatility:

| Chain Size | Load Rating (kg) |

|---|---|

| Small | Several hundred |

| Large | Several tons |

Importance of Standardization

Standardization plays a critical role in the manufacturing and application of DIN 763 chains. By adhering to the DIN 763 standard, manufacturers ensure that chains are compatible with a wide range of equipment. This reduces the risk of operational failures and enhances safety.

The DIN 763 standard is widely adopted in Germany and internationally. It ensures:

- Consistent quality across different manufacturers.

- Reliable performance in industrial settings.

- Safety for workers and equipment during use.

This level of standardization simplifies the selection process for users, as they can trust that any DIN 763 chain will meet their requirements.

Common Materials and Finishes

DIN 763 chains are typically made from high-quality steel or stainless steel (grades 304 and 316). These materials provide excellent strength and durability. Forging processes enhance the mechanical properties of the chains, while heat treatment improves hardness and toughness.

The finish quality of these chains is equally important. Polished surfaces and heat-treated finishes ensure resistance to corrosion and wear. Strict quality control measures during production guarantee that each chain meets the required standards.

A summary of material composition and finish quality metrics is shown below:

| Material Composition | Finish Quality Metrics |

|---|---|

| High-quality steel | Polished surface |

| Stainless Steel 304/316 | Heat treatment applied |

These materials and finishes make DIN 763 chains suitable for use in harsh environments, where durability and reliability are essential.

Construction and Design

Link Design and Manufacturing Process

The design of a Chaîne DIN 763 focuses on precision and strength. Each link is welded to ensure a uniform structure, which enhances durability and reliability. The long-link design provides flexibility, making the chain suitable for various applications, including industrial and marine use.

Manufacturers follow strict guidelines to meet both DIN 763 and EN standards. This ensures the chain performs consistently under heavy loads. The production process involves advanced forging techniques and heat treatment to improve the chain’s mechanical properties.

A summary of key manufacturing features is shown below:

| Fonctionnalité | Description |

|---|---|

| High-Quality Construction | Built with a welded structure for durability and reliability in heavy-duty applications. |

| Compliance with International Standards | Meets DIN 763 / 764 / 766 / 5685 standards, ensuring performance and safety. |

| Galvanized Finish | Provides excellent corrosion resistance, extending lifespan in harsh environments. |

| Customization Options | Offers custom branding and OEM services for personalization. |

| Competitive Pricing | Minimum order of 5 tons with flexible payment terms, including 30% T/T payment. |

Corrosion Resistance and Durability

DIN 763 chains are designed to withstand harsh environments. The galvanized finish protects the chain from rust and corrosion, making it ideal for outdoor and marine applications. Stainless steel variants, such as grades 304 and 316, offer additional resistance to chemical exposure and moisture.

The chain’s durability is further enhanced by heat treatment, which increases hardness and reduces wear over time. This makes the chain a reliable choice for long-term use in demanding conditions.

Mechanical Properties and Quality Assurance

The mechanical properties of a DIN 763 Chain are optimized for strength and safety. High-quality steel ensures the chain can handle significant loads without deformation. Heat treatment processes improve tensile strength and toughness, allowing the chain to perform well under stress.

Manufacturers implement rigorous quality assurance measures to meet international standards. Each chain undergoes testing to verify its load capacity and resistance to wear. These measures ensure the chain delivers consistent performance across various applications, from engineering to agriculture.

DIN 763 chains are suitable for general-purpose use, offering reliability in industrial, agricultural, and marine environments. Their compliance with international standards guarantees safety and performance, making them a trusted choice for professionals.

Dimensions and Specifications

Standard Dimensions and Sizes

DIN 763 chains follow precise dimensional standards to ensure compatibility and reliability. Each chain features uniform link sizes, which allow seamless integration with equipment and accessories. The long-link design provides flexibility while maintaining strength.

The dimensions of DIN 763 chains are categorized based on link diameter and pitch length. These measurements determine the chain’s load capacity and suitability for specific applications. Manufacturers produce chains in a range of sizes to meet diverse industrial needs.

| Link Diameter (mm) | Pitch Length (mm) | Approx. Weight (kg/m) |

|---|---|---|

| 4 | 26 | 0.35 |

| 6 | 36 | 0.85 |

| 8 | 48 | 1.50 |

| 10 | 60 | 2.30 |

The table above highlights common dimensions, helping users select the appropriate chain size for their requirements.

Conseil : Always verify the chain dimensions against equipment specifications to ensure proper fit and functionality.

Load Capacities and Working Load Limits

DIN 763 chains are engineered to handle significant loads. Their load capacities depend on the chain’s size, material, and manufacturing process. Each chain undergoes rigorous testing to determine its working load limit (WLL), which represents the maximum weight it can safely support.

The WLL is a critical factor in chain selection. It ensures safety during operations and prevents overloading. For example, a chain with a 10 mm link diameter typically has a WLL of several tons, making it suitable for heavy-duty tasks.

Key considerations for load capacities include:

- Material Strength: High-quality steel and stainless steel provide superior load-bearing capabilities.

- Heat Treatment: Enhanced tensile strength ensures the chain can withstand stress without deformation.

- Safety Factor: Manufacturers apply a safety factor to account for dynamic forces and unexpected loads.

Users should always adhere to the specified WLL to avoid accidents and equipment damage.

Compliance with DIN 763 Requirements

DIN 763 chains must meet strict compliance standards to ensure safety and performance. These requirements cover dimensions, materials, and manufacturing processes. Chains that adhere to DIN 763 standards undergo thorough inspections and testing to verify their quality.

Compliance ensures:

- Uniformity: Chains from different manufacturers maintain consistent dimensions and performance.

- Reliability: Adherence to standards guarantees durability and resistance to wear.

- La sécurité : Proper testing minimizes the risk of failure during use.

Manufacturers often include certification labels to indicate compliance with DIN 763 standards. Users should look for these labels when purchasing chains to ensure they meet industry requirements.

Remarque : Non-compliant chains may pose safety risks and fail to deliver reliable performance.

Applications of DIN 763 Chains

Industries and Use Cases

DIN 763 chains find widespread use across various industries due to their strength, durability, and versatility. These chains are particularly popular in sectors where reliability and safety are critical.

- Marine Industry:

The marine sector frequently uses these chains for anchoring, mooring, and towing applications. Their corrosion-resistant properties make them ideal for saltwater environments. - Construction and Engineering:

Construction sites rely on DIN 763 chains for tasks such as securing scaffolding, lifting heavy materials, and stabilizing structures. Their high load capacity ensures safe and efficient operations. - Agriculture:

Farmers use these chains for equipment towing, securing loads, and other general-purpose tasks. Their durability makes them suitable for outdoor use in varying weather conditions. - Transportation and Logistics:

These chains are essential for securing cargo during transit. Their standardized dimensions ensure compatibility with various tie-down systems. - Industrial Manufacturing:

Factories use DIN 763 chains in conveyor systems, assembly lines, and material handling equipment. Their long-link design provides flexibility and ease of use.

Faits amusants: The long-link design of DIN 763 chains allows them to adapt to different applications, making them a versatile tool in many industries.

Benefits in Specific Applications

The unique features of DIN 763 chains offer several advantages in specific applications:

- Marine Applications: The galvanized or stainless steel finish protects against rust, ensuring long-term performance in harsh marine environments.

- Heavy Lifting: Their high tensile strength allows them to handle significant loads without deformation, making them reliable for lifting and hoisting tasks.

- Outdoor Use: The chains resist wear and tear, even when exposed to extreme weather conditions, making them suitable for agricultural and construction purposes.

- Industrial Settings: Their uniform link dimensions ensure smooth operation in conveyor systems and other machinery.

These benefits make DIN 763 chains a preferred choice for professionals who require dependable and long-lasting equipment.

Limitations in Certain Environments

While DIN 763 chains excel in many applications, they have limitations in specific environments:

- High-Temperature Settings: Prolonged exposure to extreme heat can weaken the chain’s material, reducing its load capacity.

- Chemical Environments: Although stainless steel variants resist corrosion, exposure to highly acidic or alkaline substances may degrade the chain over time.

- Dynamic Loads: These chains are not designed for continuous dynamic loading, such as in high-speed machinery or repetitive lifting operations.

- Lifting and Hoisting: DIN 763 chains are not rated for overhead lifting tasks. Specialized lifting chains, such as those adhering to DIN 5687 standards, are better suited for such applications.

Note: Always assess the operating environment and application requirements before selecting a DIN 763 chain to ensure safety and performance.

Comparisons and Limitations

Static vs. Dynamic Use

DIN 763 chains perform well in static applications, where loads remain stationary or change infrequently. These chains excel in tasks like securing cargo, anchoring, or stabilizing structures. Their long-link design provides flexibility, making them easy to handle and adjust.

In dynamic applications, where loads move continuously or experience frequent shifts, DIN 763 chains face limitations. The repetitive stress can lead to wear and fatigue over time. For example, conveyor systems with high-speed operations may require chains specifically designed for dynamic use. Selecting the right chain for the job ensures safety and extends the chain’s lifespan.

Conseil: Always evaluate the type of load movement before choosing a chain to avoid premature wear or failure.

Comparison with DIN 766 Chains

DIN 763 and DIN 766 chains share similarities but serve different purposes. DIN 766 chains feature shorter links, which provide higher strength and reduced elongation under load. These characteristics make them ideal for applications requiring precise fitment, such as marine windlasses or hoists.

DIN 763 chains, with their long-link design, offer greater flexibility and versatility. They are easier to handle and more suitable for general-purpose tasks. The table below highlights key differences:

| Fonctionnalité | DIN 763 Chains | DIN 766 Chains |

|---|---|---|

| Link Design | Long-link | Short-link |

| Flexibilité | Haut | Modéré |

| Strength | Suitable for general use | Higher strength for specific tasks |

| Common Applications | Cargo securing, towing, agriculture | Marine windlasses, lifting systems |

Choosing between these chains depends on the specific requirements of the task, such as load type, environment, and precision needs.

Limitations in Lifting and Hoisting

DIN 763 chains are not designed for overhead lifting or hoisting tasks. Their long-link design, while versatile, lacks the structural integrity required for such operations. Chains used for lifting must meet stricter standards, such as DIN 5687, which ensures higher tensile strength and safety factors.

Using DIN 763 chains for lifting can pose safety risks, including chain deformation or failure under heavy loads. To make informed decisions, users should define criteria, gather data, and analyze options. The table below outlines a systematic approach:

| Step | Description |

|---|---|

| Define criteria | Establish clear metrics for comparison. |

| Gather data | Collect relevant information for each option. |

| Analyze similarities and differences | Evaluate how each set of requirements aligns with the goals. |

| Compare against goals | Assess which option best meets the desired objectives. |

| Consider budget and constraints | Factor in financial and operational limitations. |

| Make informed decisions | Choose the most suitable option based on the analysis. |

Note: For lifting tasks, always select chains specifically rated for hoisting to ensure safety and compliance with industry standards.

Maintenance and Safety

Inspection and Cleaning Guidelines

Regular inspection ensures the safety and longevity of DIN 763 chains. Users should examine chains for visible damage, such as cracks, deformation, or excessive wear. Checking for rust or corrosion is equally important, especially for chains used in outdoor or marine environments.

Cleaning chains removes dirt and debris that can accelerate wear. A soft brush or cloth works well for removing surface grime. For chains exposed to harsh conditions, rinsing with water and applying a mild detergent can help maintain their finish. After cleaning, drying the chain thoroughly prevents moisture-related damage.

Conseil: Apply a light coat of lubricant after cleaning to reduce friction and protect against rust.

Safe Usage and Load Management

Proper usage minimizes risks and ensures the chain performs as intended. Users must verify the chain’s working load limit (WLL) before applying it to a task. Overloading a chain can lead to failure, posing safety hazards.

When securing loads, distribute weight evenly across the chain to avoid stress concentration. Avoid sudden movements or jerks, as dynamic forces can exceed the chain’s capacity. For towing or anchoring, ensure the chain is securely fastened to prevent slippage.

Alert: Never use DIN 763 chains for overhead lifting. Specialized lifting chains are required for such tasks.

Proper Storage and Lifespan Extension

Storing chains correctly prevents unnecessary wear and extends their lifespan. Chains should be kept in a dry, cool environment away from direct sunlight or moisture. Hanging chains on hooks or racks prevents tangling and reduces stress on individual links.

For chains used in corrosive environments, applying a protective coating before storage can preserve their finish. Periodic inspections during storage ensure chains remain in good condition and ready for use.

Emoji Reminder: 🛠️ Regular maintenance and proper storage keep chains reliable and safe for long-term use.

DIN 763 chains play a vital role in industries requiring strength, durability, and reliability. Their standardized design ensures compatibility and safety across diverse applications, from marine to construction. Proper maintenance, including regular inspections and cleaning, extends their lifespan and prevents failures.

Conseil: Always verify compliance with DIN 763 standards to ensure safety and performance.

Selecting the right chain requires understanding load requirements and environmental conditions. Informed decisions help users maximize efficiency while minimizing risks. By adhering to these guidelines, professionals can rely on DIN 763 chains for long-term success.

FAQ

What is the difference between DIN 763 and DIN 766 chains?

DIN 763 chains have a long-link design, offering flexibility and versatility for general use. DIN 766 chains feature shorter links, providing higher strength and precision for specific tasks like marine windlasses. Users should choose based on application requirements.

Can DIN 763 chains be used for lifting heavy loads?

No, DIN 763 chains are not rated for overhead lifting. They are suitable for securing, towing, and general-purpose tasks. For lifting, users should select chains that meet stricter standards, such as DIN 5687.

Conseil: Always verify the chain’s working load limit before use.

How can I prevent corrosion on DIN 763 chains?

Applying a protective coating or using stainless steel variants (grades 304 or 316) helps prevent corrosion. Regular cleaning and drying after exposure to moisture also protect the chain’s finish.

Are DIN 763 chains compatible with all equipment?

Yes, DIN 763 chains follow standardized dimensions, ensuring compatibility with most equipment. However, users should always verify the chain’s size and specifications against their equipment requirements to ensure proper fit.

How often should DIN 763 chains be inspected?

Chains should be inspected before each use and periodically during storage. Look for signs of wear, deformation, or corrosion. Regular inspections ensure safety and extend the chain’s lifespan.

Emoji Reminder: 🔍 Regular checks prevent unexpected failures.